I-Hand File Metal File Tool-Abrasive Tools

Imininingwane Eyisisekelo

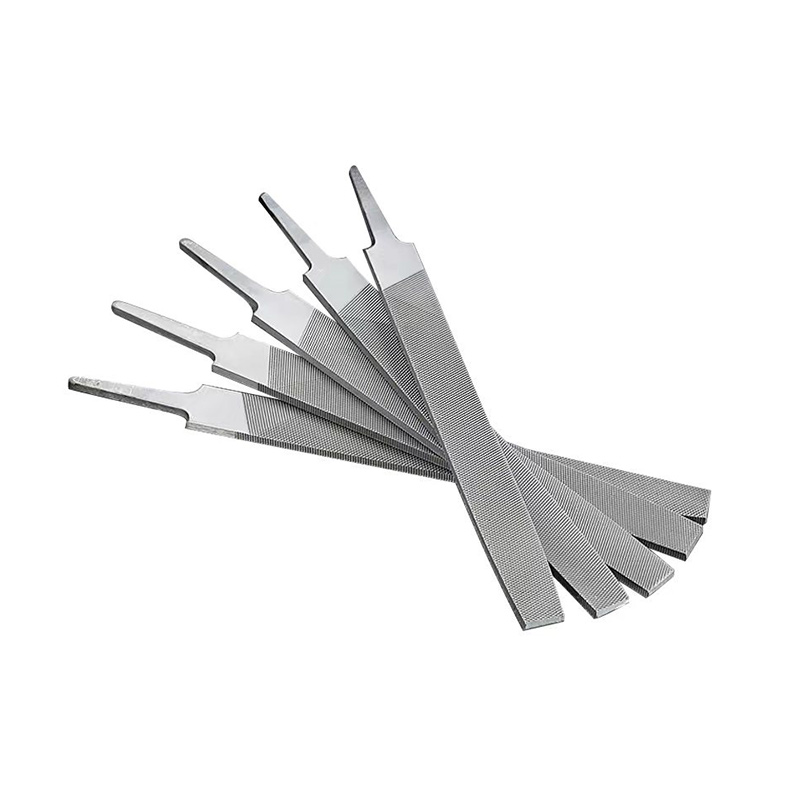

Igama Lomkhiqizo: Amafayela Esandla (Zonke izinhlobo zamafayela atholakalayo)

Material: I-High Carbon Steel T12 (Ibanga lempahla engcono kakhulu)

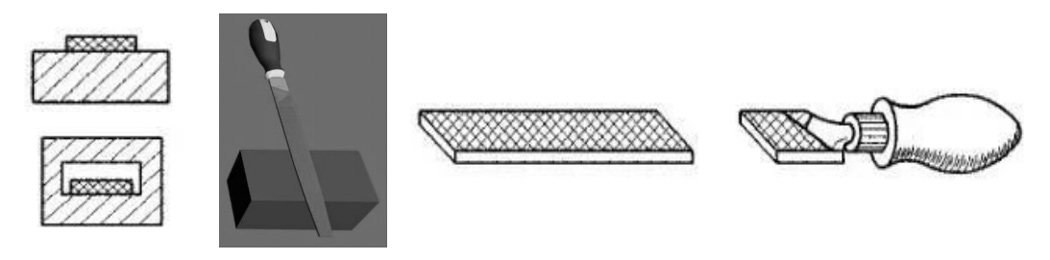

Isicelo: Indiza yefayela, indawo eyi-cylindrical kanye ne-convex arc surface.Isetshenziselwa ukucubungula okuncane kwensimbi, ukhuni, isikhumba nezinye izingqimba zangaphezulu.

Uhlobo lokusika: I-Bastard/yesibili/Ibushelelezi/I-Dead Smooth

Ububanzi: 12-40mm

Ubukhulu: 3-9 mm

Ukucaciswa: 100mm/125mm/150mm/200mm/250mm/300mm/350mm/400mm/450mm/ ngokwezifiso

Inkokhelo & Imininingwane Yokulethwa: TT/LC&Ngaphakathi kwezinsuku ezingama-30-50 ngemuva kokuqinisekisa i-oda

Isitifiketi: GB/T 19001-2016/ISO9001:2015

Inzuzo: Ihlala isikhathi eside, isikhathi eside sokusebenza, ukusetshenziswa okuphephile, ukuqina okuphezulu

Product Yethula

Umkhiqizo wenziwe ngensimbi yensimbi ehlanzekile ye-carbon enobulukhuni obuphezulu kanye nemigqa yamazinyo ecacile.Kuyithuluzi lemanuwali elisetshenziselwa ikakhulukazi ukugaya nokugqoka izinto zensimbi.Ingasetshenziswa yodwa.

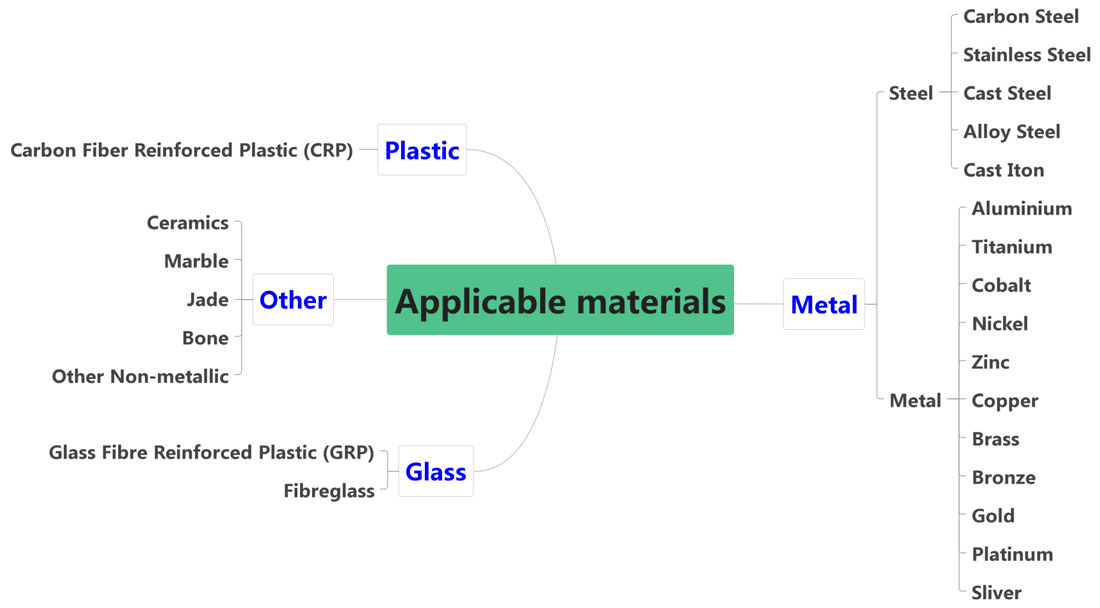

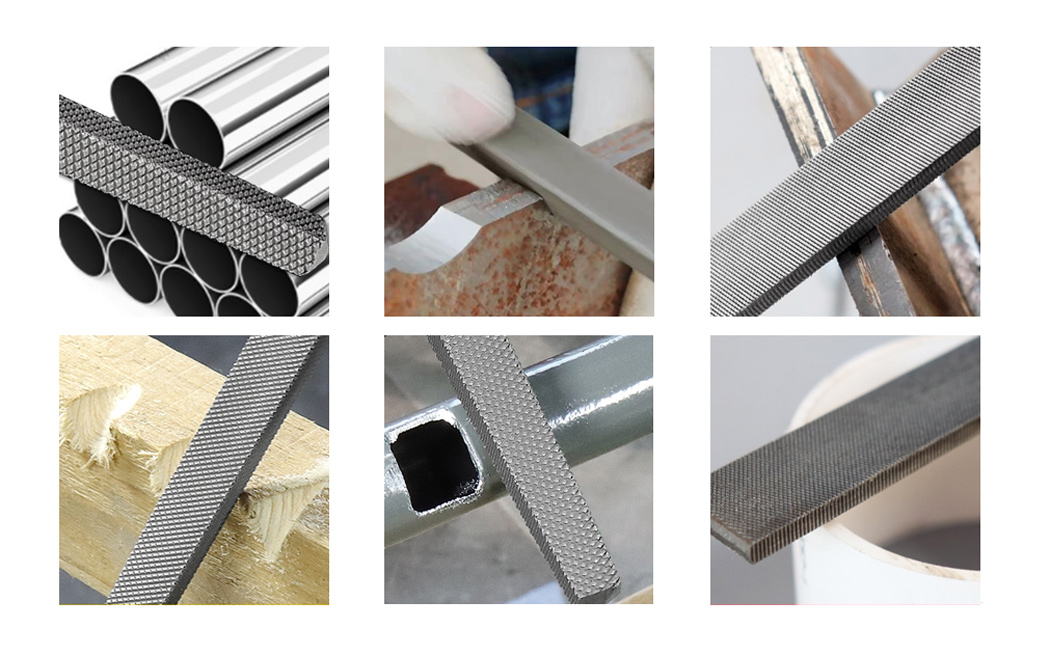

Izinto Ezisebenzayo

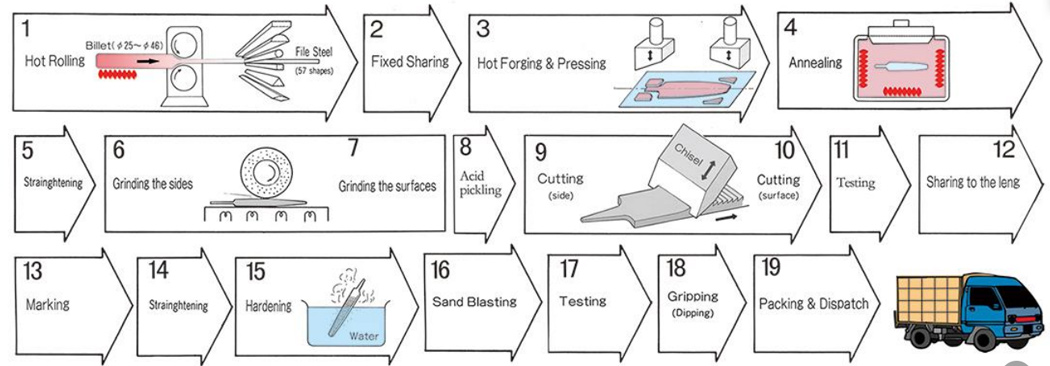

Inqubo Yezobuchwepheshe

Isithombe sephakheji

Isitayela sokubamba

Isimo Esisebenzayo

Okunye Ubukhulu

| No | Ukucaciswa Mm/Intshi | Ububanzi/mm | Ubukhulu/mm | Isisindo/g |

| I-GT10104 | 100mm/4” | 12 | 3 | 32 |

| I-GT10105 | 125mm/5” | 14 | 3.2 | 40 |

| I-GT10106 | 150mm/6” | 16 | 3.5 | 70 |

| I-GT10108 | 200mm/8” | 20 | 4.2 | 140 |

| I-GT10110 | 250mm/10” | 24 | 5.2 | 250 |

| I-GT10112 | 300mm/12” | 28 | 6.2 | 417 |

| I-GT10114 | 350mm/14” | 32 | 7.2 | 627 |

| I-GT10116 | 400mm/16” | 36 | 8 | 900 |

| I-GT10118 | 450mm/18” | 40 | 9 | 1200 |

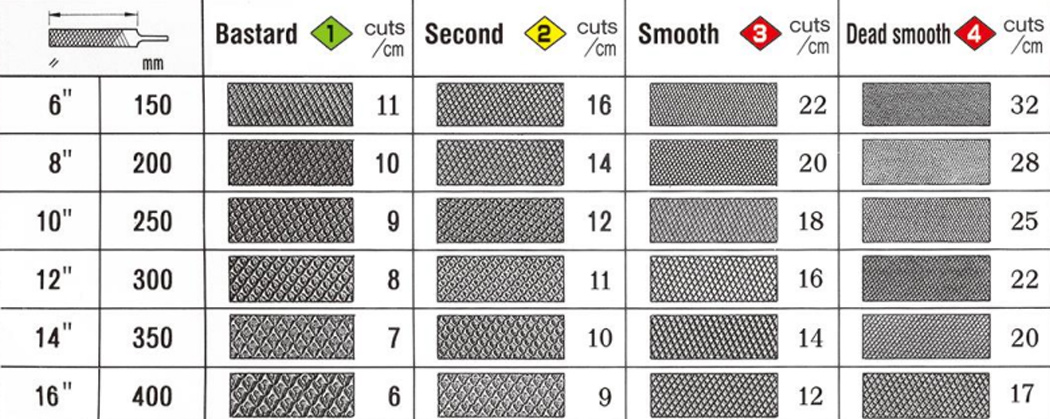

Izinhlobo Ezijwayelekile Zokusika

I-Bastard Cuts:ilungele ucezu olusebenza kanzima kanye nokubunjwa kokuqala

Ukusika kwesibili:ilungele ukwenziwa kwemishini enemvume yomshini engaphezu kuka-0.5mm.Ukusika ivolumu enkulu machining kungenziwa ukuze kususwe ingxenye ngesibonelelo esengeziwe somsebenzi.

Ama-Smooth Cuts:ilungele umshini ngesabelo somshini we-0.5-0.1mm.Angapholishwa ngokucophelela ukuze asondele kusayizi odingekayo wesiqephu somsebenzi.

Ama-Dead Smooth Cuts:Ifayela le-Dead Smooth Cuts yifayela elinamazinyo amancane kakhulu.Umphumela wayo wokusika mncane kakhulu.Isetshenziswa kakhulu ukunquma ubulukhuni bengxenye yomsebenzi.Isetshenziselwa ukuqedela umsebenzi ongaphezulu.

Izinzuzo Zomkhiqizo

1. Singumkhiqizi wamafayela ensimbi ochwepheshe kusukela ngo-1992. Ngeminyaka engu-30 yamathuluzi abrasive, futhi isikhathi sokugaya izingcezu zomsebenzi nakanjani side kunesabanye.

2. Impahla yethu iyi-100% yangempela ye-Carbon Steel T12.Enye imboni yasebenzisa impahla enezindleko eziphansi ukwenza ikhwalithi eshibhile.

3. Ukushisa okuphezulu kokucisha ukuthuthukisa ukumelana nobulukhuni bemikhiqizo.

4. Ithiphu yezinyo libukhali, elinikeza isiqinisekiso sokugaya ngokushesha, futhi ithiphu lezinyo likwazi ukumelana nokuguga ngemva kwenqubo yokucisha.

5. Ukuxhumeka kwesibambo kusebenzisa ubuchwepheshe bokuxhumana obukhethekile ukuze kuvinjwe isibambo ukuthi siwe ngesikhathi sokusetshenziswa.

Ezinye Izinzuzo

● Ama-oda Amancane Amukelwe

● Igama lomkhiqizo elenziwe ngokwezifiso

● Ukulethwa Ngokushesha

● Abasebenzi Abanolwazi

● Ukusebenza Okuhle Komkhiqizo

● Umkhiqizo Oluhlaza

Ukupakisha nokuthunyelwa

● Isisindo Esiphelele: 24kg

● Isisindo Esiphelele: 25kg

● Thekelisa I-Carton Ubukhulu L/W/H: 37cm×19cm×15cm

● Imbobo ye-FOB: Noma iyiphi imbobo

● Isikhathi Sokuhola: Izinsuku ezingu-7-30

Amathiphu Afudumele

● Ukuze ugweme imikhiqizo nezinqubo ezingalungile emsebenzini, kunconywa ukuthenga izinhlobo ezintathu zamafayela: i-bastard, yesibili kanye nebushelelezi, engandisa ukusebenza kahle komsebenzi.

● Ungasebenzisi ifayela elisha kunsimbi eqinile.Ungasebenzisi amafayela ensimbi eqinisayo.

● Uma izingcezu ze-aluminium noma okunye ukubunjwa kumaholoholo noma kunesihlabathi, ngemva kokukhuhlwa, singasebenzisa ifayela.

● Ukusebenzisa amathuluzi kungaba yingozi, hlala unakekele futhi uqhelelane Nezingane.

● Gqoka izingubo zamehlo ezivikelayo endaweni yokusebenza ngaso sonke isikhathi.

● Khetha uhlobo olulungile nosayizi wethuluzi lomsebenzi

● Sebenzisa uhlangothi olulodwa lwefayela kuqala.ngemva kokuba buthuntu, bese ujikela kolunye uhlangothi lwefayela.

Ukusebenzisa amathuluzi kungaba yingozi, hlala unakekele futhi uqhelelane Nezingane.

Gqoka izingubo zamehlo ezivikelayo endaweni yokusebenza ngaso sonke isikhathi.

Khetha uhlobo olulungile nosayizi wethuluzi lomsebenzi.

FAQ

1.Ifayela lesandla lisetshenziselwa ini?

Isetshenziselwa ukuqeda kahle kwensimbi, ukhuni, isikhumba nezinye izindawo.Ngokusho kwephrofayili ehlukile, ingahlukaniswa ngefayela eliyisicaba, ifayela eliyindilinga, ifayela lesikwele, ifayela elingunxantathu, ifayela ledayimane, ifayela eliyindilinga eliyisigamu, ifayela lommese nokunye.

2.Lithini igama lefayela lesandla?

Ifayela eliyisicaba elinomumo ongunxande.Eyaziwa nangokuthi ifayela lebhodi.

3.Ngilikhetha kanjani ifayela elilungile?

(1).Ukukhethwa komumo wesigaba sefayela.Umumo wesigaba sefayela uzokhethwa ngokuya ngesimo sengxenye ezogcwaliswa, ukuze lezi zimo ezimbili zihambisane.Lapho ufaka i-arc surface yangaphakathi eyindilinga, khetha ifayela eliyindilinga eliyindilinga noma ifayela eliyindilinga (ucezu lomsebenzi olunobubanzi obuncane);Lapho ufaka indawo engaphakathi yekhona, khetha ifayela elingunxantathu;Lapho ufaka indawo engaphakathi ye-engeli yesokudla, ifayela eliyisicaba noma ifayela lesikwele lingakhethwa.Uma usebenzisa ifayela eliyisicaba ukuze ufake i-engeli engaphakathi kwesokudla, naka ukwenza indawo encane (unqenqema olubushelelezi) yefayela ngaphandle kwamazinyo eduze kwendawo eyodwa ye-engeli engaphakathi kwesokudla ukuze ugweme ukulimaza i-engeli engakwesokudla.

(2).Ukukhethwa ifayela izinyo ukujiya.Ubukhulu bamazinyo wefayela kufanele bukhethwe ngokuvumelana nesabelo somsebenzi, ukunemba kwemishini kanye nezakhiwo ezibonakalayo.Ifayela lezinyo eliqinile lilungele ukukhanda izingcezu zomsebenzi ezinemvume enkulu, ukunemba okuphansi kwe-dimensional, ifomu elikhulu nokubekezelelana kwesikhundla, inani elikhulu lokuma okungaphezulu kanye nezinto ezithambile;Kunalokho, khetha ifayela lezinyo elihle.Uma isetshenziswa, kufanele ikhethwe ngokuvumelana nemvume yomshini, ukunemba kwe-dimensional kanye nobukhulu obuphezulu obufunwa yi-workpiece.

(3).Ukukhethwa kosayizi wefayela kanye nokucaciswa.Usayizi kanye nokucaciswa kwefayela kuzokhethwa ngokuya ngosayizi we-workpiece okufanele icutshungulwe kanye nesibonelelo somshini.Lapho ubukhulu bomshini bukhulu futhi isibonelelo sikhulu, ifayela elinencazelo yesayizi enkulu lizokhethwa, ngokuphambene nalokho, ifayela elinencazelo yesayizi encane lizokhethwa.

(4).Ukukhethwa kwephethini yezinyo lefayela.Iphethini lezinyo lefayela kufanele likhethwe ngokuya ngezakhiwo zezinto zokwenziwa komsebenzi ezifakwayo.Uma ufaka i-aluminium, ithusi, insimbi emnene nezinye izingcezu zomsebenzi ezithambile, kungcono ukhethe iphethini yezinyo elilodwa (izinyo lokugaya) ifayela.Ifayela lezinyo elilodwa line-engeli enkulu ye-rake, i-engeli encane ye-wedge kanye ne-chip enkulu yokubamba i-groove.I-chip akulula ukuvinjwa futhi unqenqema lokusika lubukhali.