Ukukhethwa nokusetshenziswa kwempahla kanye nemodeli yesisiki sokugaya kuncike ezintweni zokucubungula kanye nenjongo yokucubungula.

Ngezansi kukhona amabanga ajwayelekile wokusika ukugaya kanye neziphakamiso zokukhetha:

I-1.I-high-speed steel (HSS) i-milling cutter: ifanele ukucubungula ezinye izinto eziqinile, njengensimbi, insimbi ekhonjiwe, insimbi engagqwali, njll. Ukukhanda kungenziwa ngokomile (akukho lubrication) noma ukupholisa okumanzi.

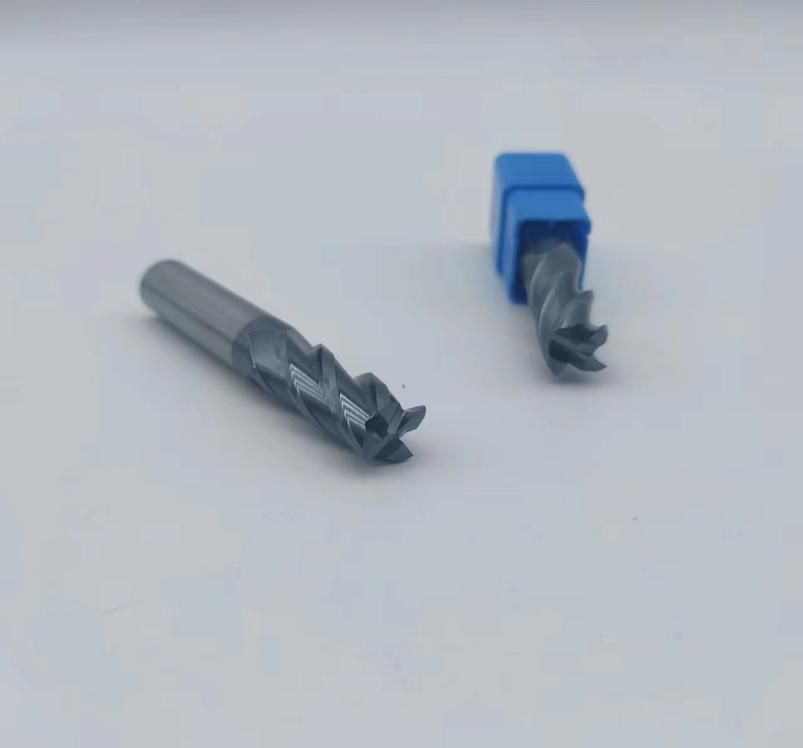

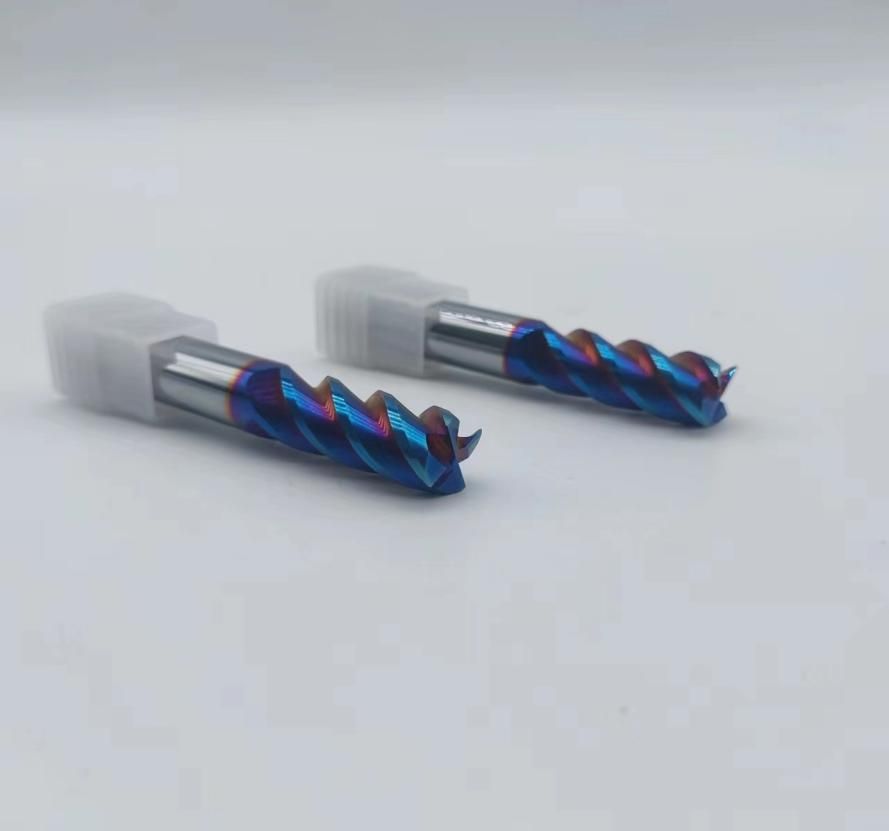

I-2.Tungsten carbide (WC) i-milling cutter: ifanele ukucubungula izinto ezinobunzima obukhulu, njenge-titanium alloy, i-high hardness alloy steel, njll Ngenxa yokuqina kwayo okuphezulu, kunconywa ukupholisa okumanzi.

I-3.PCD yokugaya i-cutter (i-polycrystalline diamond): ifanele ukucubungula izinto eziqinile kakhulu, njengezinto eziphikisayo, izitsha zobumba, ingilazi, njll. Ngenxa yokushisa kwayo okungalungile, kufanele isetshenziswe ngaphansi kokupholisa okumanzi.Uma ukhetha uhlobo lwe-milling cutter, kufanele lucatshangelwe ngokuvumelana nobunzima, ikhwalithi yendawo kanye nomthamo wokucubungula wezinto ezicutshungulwayo.Ngokuvamile, amazinyo amaningi esisiki sokugaya angasetshenziswa ukuthuthukisa ukushelela kwendawo, kuyilapho amazinyo ambalwa angasetshenziswa ukwandisa isivinini sokucubungula, kodwa kufanele futhi kuqashelwe ukugwema ukukhiqiza ukushisa ngokweqile ngesikhathi sokusetshenziswa.Ukwengeza, ukusetshenziswa kwabasiki be-milling abancane kakhulu noma abakhulu kakhulu kufanele kugwenywe, ukuze kungabangela umonakalo kubasiki abancane bokugaya, futhi abasiki be-milling abakhulu kakhulu bazobangela ukucubungula okungalingani kanye nokugqoka imfucuza.

Impilo yesevisi ye-milling cutter incike ezintweni eziningi, njengempahla, i-geometry, impahla yokucubungula, amandla okusika, isivinini sokusika kanye nendlela yokupholisa yesisiki sokugaya.Ngokuvamile, abasiki be-milling bazobhekana nokuguga nokukhathala ngesikhathi somshini, okubenza balahlekelwe ukubukhali nokunemba kwabo, okuholela ekwehleni kwekhwalithi yomkhiqizo kanye nokuncipha kokusebenza kahle kokusika.

Ukuze kunwetshwe impilo yesevisi ye-milling cutter, izici ezilandelayo kufanele zinakwe:

1.Khetha izinto ezifanele zokusika isigayo kanye nejiyomethri, bese ukhetha ngokuya ngobulukhuni, isivinini sokusika kanye nezidingo zempilo yamathuluzi zezinto ezicutshunguliwe.

2.Setha ngokunengqondo imingcele yokucubungula, njengejubane lokusika, isivinini sokuphakelayo nokujula kokusika, njll., futhi ugweme ukusebenzisa isivinini sokusika esiphezulu kakhulu kanye nesivinini sokuphakela ukuze ugweme ukuguga ngokweqile.

3.Gcina izinsimbi zokugaya zipholile futhi zigcotshiwe, sebenzisa izinto ezipholile ezifanele kanye nezinto zokugcoba ukuze ugweme ukushisa nokuguga ngokweqile.

4.Hlanza njalo futhi uhlole izisiki zokugaya, gwema umkhuba omubi wokuqongelela ama-chips namadiphozithi, futhi njalo uhlole futhi ushintshe izisiki zokugaya eziguge kakhulu.

5.Gcina futhi uvikele abasiki bokugaya ekulimaleni kwemishini, kwamakhemikhali noma okugqwalile, njengokusebenzisa amabhokisi okubhola noma amajigi, futhi ugweme ukuchayeka kumagesi ayingozi noma elangeni eliqondile.

Isikhathi sokuthumela: Mar-13-2023